I believe that the terminal wire harness you usually see is finished, but in the process of wire harness processing and production, the requirements for wire harness are quite strict. How strict are the requirements for terminal harness?

yesTerminal harness processingWhat are the requirements?

1. After the wire harness is manufactured, the quality department needs to conduct a comprehensive inspection. If the product is unqualified or not in place, it will be reworked again.

2. After the terminal is pressed, it is necessary to wear the rubber shell. This step cannot be automated, but can only be completed manually. It is also necessary to compare the first piece. The staff of the production line should be trained to ensure that the rubber shell is properly worn and cannot fall off.

3. For other complex harnesses, it may be necessary to wear sleeves, heat shrink, etc.

4. Incoming materials should be correct, raw materials should be inspected, and production scrap should be eliminated from the source.

5. After the material is determined, it is necessary to cut the wire and make the terminal. The first article needs to be done well. The subsequent production and inspection should take the first article as the standard.

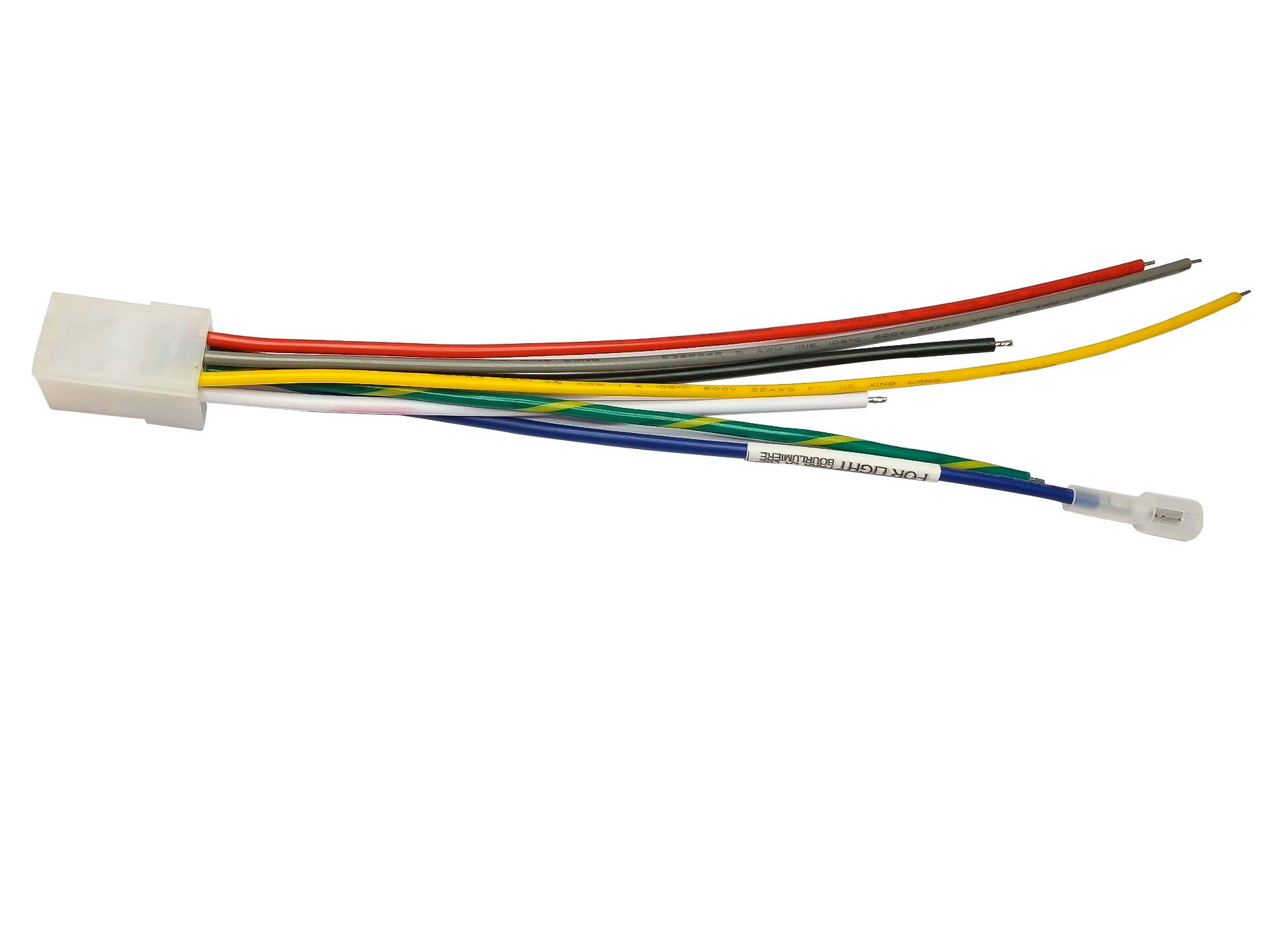

Terminal line is mainly used for the connection between internal circuits of electronic equipment. They can transmit current or signal inside the appliance, so that the normal use of electronic equipment cannot be separated from terminal line! At present, there are three main standards for domestic terminal connecting wire: UL standard, 3C standard and VDE standard. The internal conductor of terminal connecting wire is generally tinned copper or bare copper. The following is an analysis of the structure and composition of the terminal connection line:

1. The raw material of sheath shall be heat-resistant PVC sheath material imported from Japan.

2. The shielding layer of the terminal connecting wire adopts the tinned soft copper wire with a diameter of 0.1mm or more, which is horizontally rolled or braided, to improve the anti-interference and anti-noise capability of the cable.

3. The insulation materials are mainly made of high-performance heat-resistant PVC insulation materials imported from Japan, which are semi-hard, soft and hard;

4. The conductor of terminal connecting wire is tinned copper wire with diameter of 14-30AWG in Europe and America. There are three conductor methods for terminal connecting wire and electrical flexible copper wire with sectional area of 0.3mm2-2.0mm2: stranded conductor, OS-1 (TCW) conductor and solid conductor.

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd