1、 Blanking

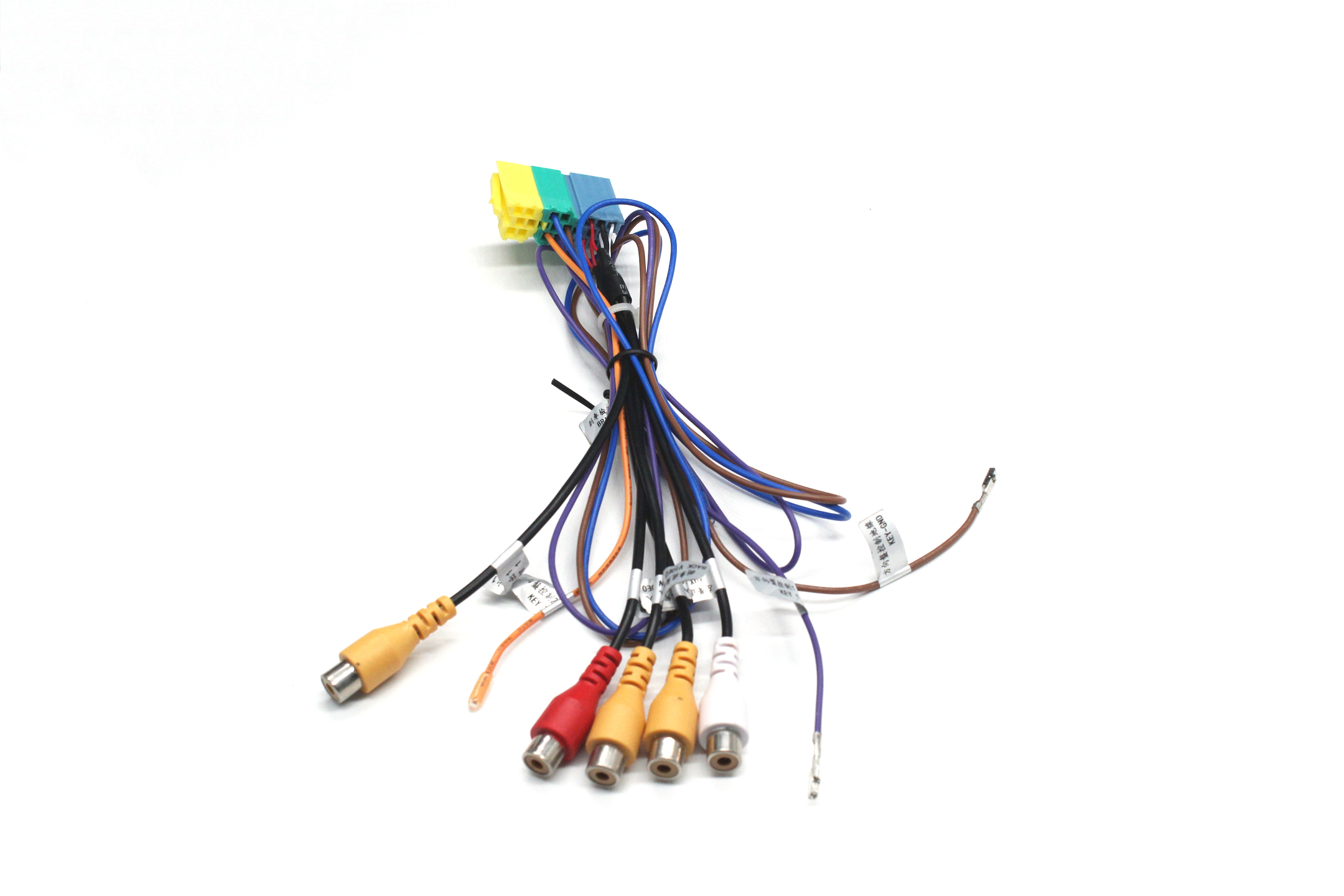

Electric wire harnessSheath wire and short circuit connection: the wire core is not damaged, the size is correct, and the wire core size is appropriate and should not be too long.

2、 Welding

① An appropriate amount of tin, too much tin will puncture the tape, affect the winding of the tape, and cause a short circuit and fire.

② The tape winding shall completely wrap the welding point, and there shall be at least one lap of overlapping winding from the beginning to the end. The tape winding shall be smooth, and the end shall be pressed flat, without warping.

3、 Terminal crimping

① Visually check whether the terminal crimping is good, and whether the copper core is broken due to too tight crimping or too loose, causing the terminal crimping not tight and falling off.

② The copper wire must be visible in the terminal transition area.

③ The terminal shall not be excessively twisted or deformed.

④ Paste your own job number.

4、 Plug-in

① The terminal is inserted in place based on barb locking.

② Insert the terminal into the correct hole position. After the terminal is inserted into the plastic case, you will hear a "bang", and then add a pull back action to ensure that the terminal will not fall off.

③ Paste your own job number.

5、 Inspection

① Appearance: whether the blanking core is too long; Winding quality of welding tape; Whether the terminal crimping is good, whether the plug-in terminal is inserted incorrectly or missing, whether the terminal falls off, and whether the insertion position is correct.

Test method: visual sample comparison.

② Size: whether the size is correct, and whether the sleeve is too long or too short.

③ Others: whether the use of fuse meets the requirements, whether the operation of each link meets the regulations, and whether the production process meets the requirements of customers.

6、 Packaging

When packaging the electric vehicle harness, there shall be no more, less, mixed or wrong packaging, the handwriting shall not be blurred, and the label shall be clear and clear at a glance.

7、 Warehousing

The storage place of electric vehicle harness shall be dry and waterproof, and the classification shall be clear.

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd