aboutTerminal harness processingAccording to the tester, the surface is not an easy thing, and the standard of important surface test is not easy to grasp. If different inspectors are engaged in the inspection of unified products, different conclusions may be drawn. Even so, as long as we really learn and master the standards, continue to accumulate experience, and test with the help of standard samples when necessary, we can do a good job in surface testing of products. The following terminal harness processing factory will introduce to you:

Conditionally test the roundness level to see whether there are any defects, such as curling, roundness, cracks, inclusions, kinks, etc., as well as major mechanical damage scars, pits, peeling, burrs, corrosion black spots, etc.

Whether the surface is smooth and clean, and whether there are triangle openings, burrs, cracks, folds, inclusions, major scars, pits, corrosion black spots and other phenomena caused by mechanical damage. It is worth mentioning that the oxidation degree of copper wire is normal for ordinary golden yellow, slight oxidation for light red, and significant oxidation for dark red and blue surfaces. Any phenomenon showing significant oxidation should be judged as waste. The aluminum wire shows many defects in the production process, so the overhead transmission line should be strictly controlled.

Compared with the surface of aluminum wire, the conductor shall be tightly and neatly twisted without looseness, kink of single conductor, jumping or protruding of single conductor, and fracture of single conductor. In addition, the welded joints on the single line shall be round and have met the welding conditions for corrosion protection. The expanded part of the joint shall not be allowed to cross twice the diameter tolerance. The distance between the two welded joints on the single line shall also meet the standard. The distance between the two welded joints on the unified single line shall not be less than 15m. The distance between the two welded joints on the non-unified single line in the unified layer shall not be less than 5m for the inner layer and 15m for the outer layer, When the copper core is a single copper wire, welding is not allowed.

The test of the surface and layout size of the terminal wire speed machining is usually conducted at the same time. The quality of the product depends on its good or bad function, but its surface quality and layout size also account for a certain proportion. The surface and layout size of the product will affect the function of the terminal wire harness machining.

1. Local thinning will cause local heating, increase resistance and accelerate the aging of insulation.

2. Oxidized and rusty black spots interfere with conductor joints, resulting in increased resistance and aging of insulation.

3. The mechanical strength of the interference conductor is damaged or scratched.

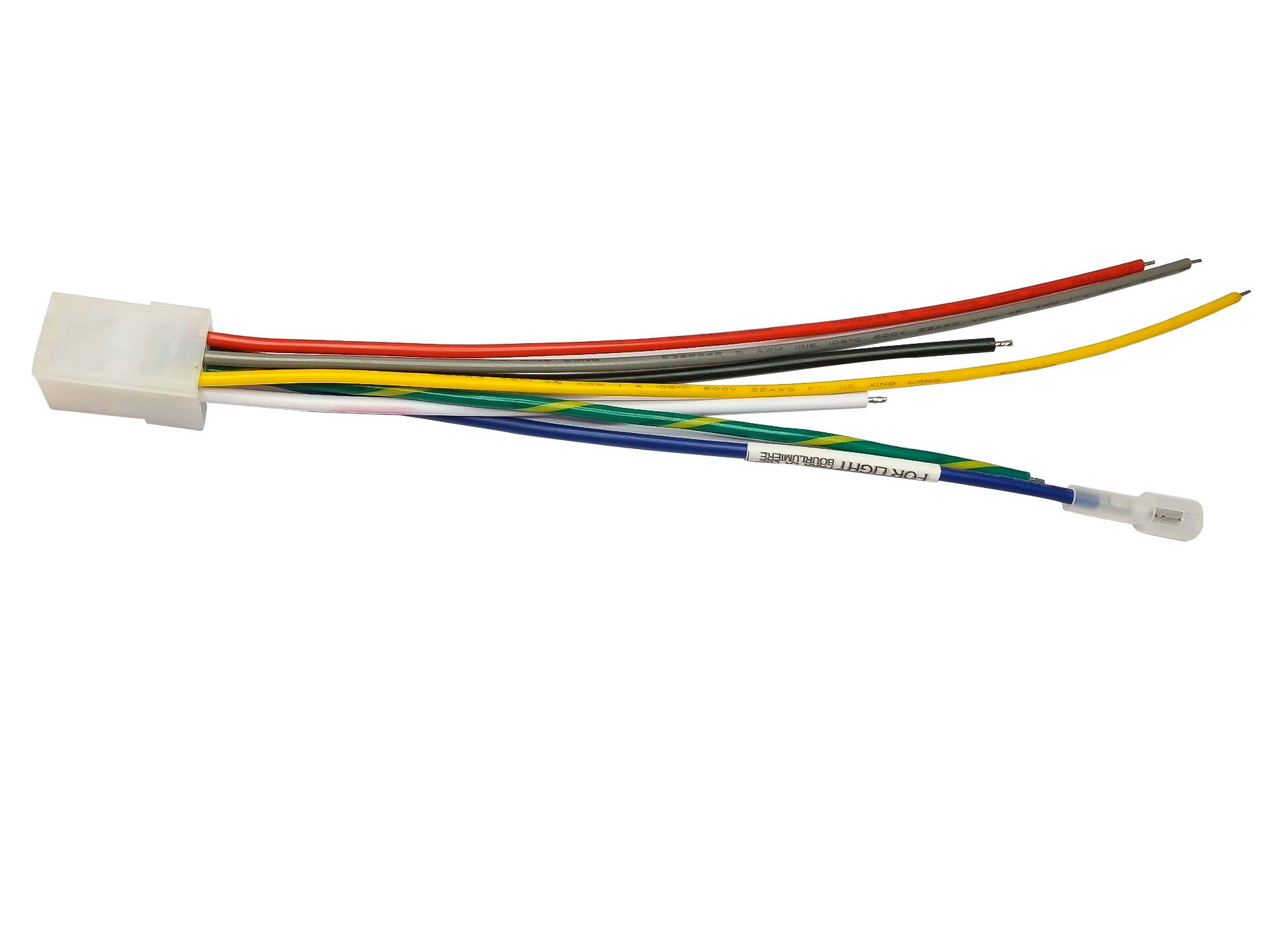

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd