IElectric wire harnessPerformance characteristics of

1. Power line and motor line

These two parts are the core parts of the electric vehicle harness. Before the production of the power harness, the allowable current value determined is below 15A, including 15A, and the cross-sectional area of the copper wire is 1.5mm ², The current value of the motor wire is larger, reaching more than 15A and less than 22A, and the sectional area of the copper wire is 2.0mm ²。

2. Lock wire to control weak current

The current intensity of the harness here is not high, ranging from 1.0A to 3.0A, so 0.5mm ² The cross-sectional area of is enough.

3. Light, horn, alarm harness

Electronic horn is a warning sound component set for safe driving. Almost all horns used in electric vehicles are active. Similarly, after in-depth research with customers, the data given is that the current intensity is 1.0A~3.0A, so the cross-sectional area is 0.5 mm2.

4. Data communication harness

The minimum allowable current of the harness is below 0.5A, and the wire diameter is 0.24mm ², Obviously, this combination is sufficient for signal transmission of various parts of electric vehicles.

Generally speaking, if the wire diameter is higher than the above specified value, the resistance of the harness is too large, and the voltage on the harness will be large when the large current such as starting the car passes through, which can reach more than 2V, causing the controller to enter the undervoltage protection prematurely. Let's take 36V as an example. If the sectional area of the harness is too small, its internal resistance will increase, which is equivalent to a series resistance. When the battery voltage is 36V and the current flowing exceeds 15A, according to Ohm's law, if the internal resistance of the harness exceeds 0.1 ohm, the upper limit voltage will reach about 2V, and the voltage supplied to the controller is only 34V. When the battery voltage drops to 33V, the voltage supplied to the controller is only 31V, and the controller enters the undervoltage protection, but the battery is not fully discharged.

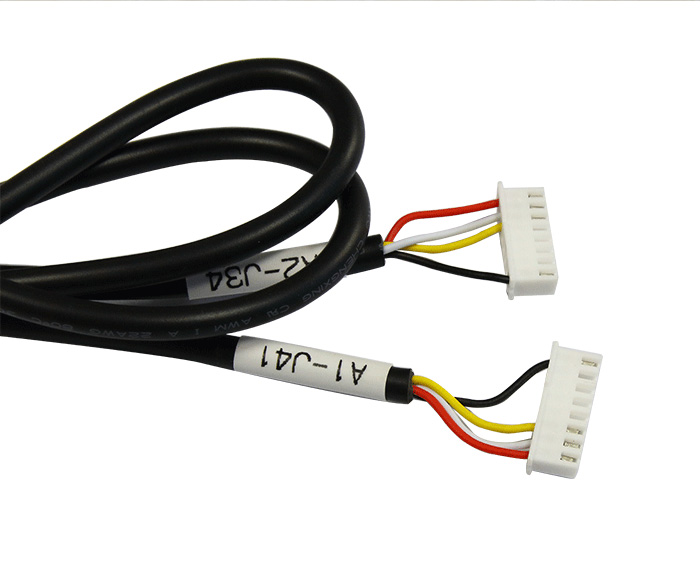

2、 Structure of electric vehicle harness

Electric vehicle harness is divided into main harness and branch harness, which shall be classified according to the system configuration of electric vehicle. The main harness is divided into battery power supply system harness, power switch harness and control system main power harness; The branch harness is divided into lighting signal harness, control system signal harness, combination switch harness, etc. The harness of lighting signal system can be divided into front lamp, front turn signal lamp, rear lamp, rear turn signal lamp, brake lamp, license plate lamp harness, etc. Generally, plastic connectors are used to connect harness and harness as well as harness and electronic components. Generally, manufacturers use the number of holes of connectors to distinguish. The main circuit harness of the whole vehicle is mostly centered on the controller and extends to the front and rear of the vehicle respectively.

3、 Specification of electric wire harness

The cross sectional area of wires in electric vehicle harness is different, and the allowable current value of wires with different cross sectional areas is also different. Generally speaking, the output line of the battery, the trunk line of the harness, the main power line of the control system, the power lock, and the connection line of the battery pack should be 1.5mm or more; The lighting signal system and combination switch are mostly more than 0.5mm conductors; More than 0.15mm wires are used for braking power failure and parking switch. Reasonable wiring harness processing and design is an important guarantee for the quality of electric vehicle products. Under the social background of advocating the concept of environmental protection, electric vehicles are becoming more and more popular. The harness manufacturer should actively study the layout method of the electric vehicle harness circuit to minimize the circuit fault of the electric vehicle.

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd