Type and composition of automobile wire harness

According to the different structure of automobile harness, it can be divided into full utilization harness, partial utilization harness and link system; According to different service modes, it is divided into loss system harness and waiting system harness; According to the number of service attachment sources, it can be divided into infinite load harness and finite load source harness. In addition to these, there is another classification, which is divided into main harness and small harness according to the number of parts. The main harness includes engine harness, floor harness, instrument panel harness, etc., and the small harness includes ceiling harness, reversing radar harness, door harness, etc.

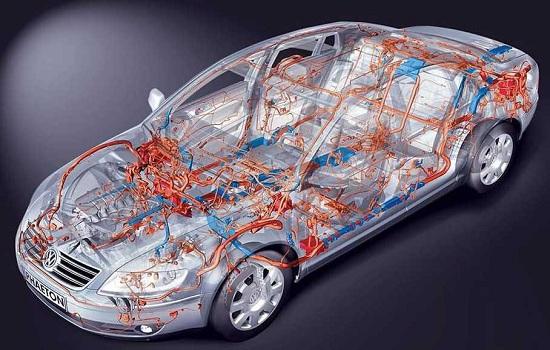

The so-called wire harness is to bind all kinds of wires with insulating materials, and integrate wires of different colors and specifications into one, which is more complete and unified, and convenient for its safety. 60% of the actual current carrying capacity of the wire and 60% to 100% of the actual current carrying capacity of the wire are applicable to the two types of electrical equipment that work for a long time and a short time, respectively. Select the cross-sectional area of the selected wire according to the load current of the automobile electrical equipment. In order to easily understand the wires in each wire harness, different colors and letters representing colors are used. The harness is generally composed of plastic parts, terminals, wires, line protectors, rubber parts, brackets, fasteners and other attachments (including tapes and sleeves), which are assembled according to certain process steps. If Plato is made according to the proportion of the cost of harness raw materials, the cost of wires, plastic parts and terminals accounts for the largest proportion of the cost of the three materials. The raw materials of wire harness are mainly purchased parts. The main method to control the cost of raw materials is to optimize the cost of raw materials of wires, plastic parts and terminals through benchmarking and VAVE.

Material function and process production of harness products

The wire requirements in various parts of the car harness are strict and unique. Most of them are in terms of their electrical performance, temperature resistance and material emission. For example, the wire of engine harness must be resistant to high temperature, oil, vibration and friction; The wire on the automatic transmission is resistant to high temperature, hydraulic oil and good stability; The harness on the luggage compartment lid must maintain its inherent elasticity at low temperatures. Therefore, cold elastic conductor should be selected to ensure its normal operation; ABS harnesses need high temperature conditions. Generally, 150-200 ℃ high temperature environment, hard insulation layer, wear-resistant, but more than 133 stranded wires should be selected.

The functions of automobile harness products can be divided into two types. One is the power line that carries the power to drive the actuator, and the other is the signal line that transmits the sensor input instructions. The thick wire with the function of carrying large current is power wire, and the thin wire without the function of carrying power is signal wire. With the change of social demand and technology, the functions of automobile modules are also increasing. Electronic technology has been widely used in modern new automobiles. Electronic control systems are closely related to automobile harnesses. The function of wire harness is similar to that of blood vessels in human body, and it is an essential element. There is a metaphor like this: the ECU and other control modules of the car are equivalent to the brain of the car, the various sensors of the car are equivalent to sensory neurons, the actuators are equivalent to motor organs, and the wiring harness is equivalent to nerves and blood vessels. At the same time, there are many contradictions and problems in the combination of technology and automobile multi-function, such as how to effectively and reasonably arrange in the limited automobile space, so that the automobile harness can play its role and function to a greater extent.

Generally, the process production of automobile wire harness can be divided into four steps: first, the opening and crimping process, second, the pre-assembly process, third, the final assembly process, and finally the final assembly process. The starting process needs to be careful and rigorous. Its accuracy affects the entire production schedule, and a slight error will affect the production efficiency. Therefore, at present, most wire harness factories adopt fully automatic wire opening equipment; The crimping process needs to determine the crimping parameters and required crimping molds according to the crimping standards and terminal types of customers. Because the crimping quality is directly related to the electrical performance, this station is a key station, which requires a crimping work instruction with special characteristics requirements, and the crimping quality is checked online in proportion according to the specified process to form a characteristic control chart; With regard to the pre-assembly process, the first task is to make the plastic parts in and out of the wire crimped by the opening line into KIT according to the process specification, which will help reduce the investment cost of the assembly line equipment, reduce the difficulty of the assembly work, and reduce the number of assembly workers. For simple car harnesses, the pre-assembly can be canceled directly, while for complex car harnesses, the pre-assembly station should be set first; Then comes the final assembly process. According to the process instructions, the pre-assembled harnesses are arranged orderly on the final assembly tooling plate, and the harness arrangement, tape winding, kart binding, rubber parts installation and other accessories are completed. The last is the post-assembly process, including the installation of support, live inspection, full-size inspection and bundling packaging.

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd