1. Repair: check whether the standard model of the wire is correct; Whether the scale meets the demand; The cutting shall be uniform, and the wire shall be free of scratches and dirt.

2. Peeling: check whether the peeling opening is flush, core wire, marshalling wire, etc. cannot be peeled, and whether the peeling scale is correct.

3. Grouping processing: whether the trimming scale is correct, whether the trimming is uniform, and whether the core wire can not be damaged during trimming.

4. Peel the endothelium: check whether the peeling opening is flush; Whether the peeling scale is correct; Whether the core wire falls off and whether the copper wire is broken; The insulator shall not fall off during half-stripping.

5. Sleeved short pipe: check whether the size and type of short pipe are correct.

6. Prepare for soldering: check whether the temperature of the tin furnace is correct; Whether the copper wires of the core wire are arranged well before the preparation of soldering, and whether there are signs of bifurcation, twists, discounts, etc; Whether the copper wire is bifurcated, big-ended, uneven, and the insulation skin is burnt after soldering preparation.

7. Solder: check whether the temperature of electric soldering iron is correct; Do not burn the insulation skin. The tin point should be lubricated and Wuxi pointed. False soldering and false soldering are not allowed.

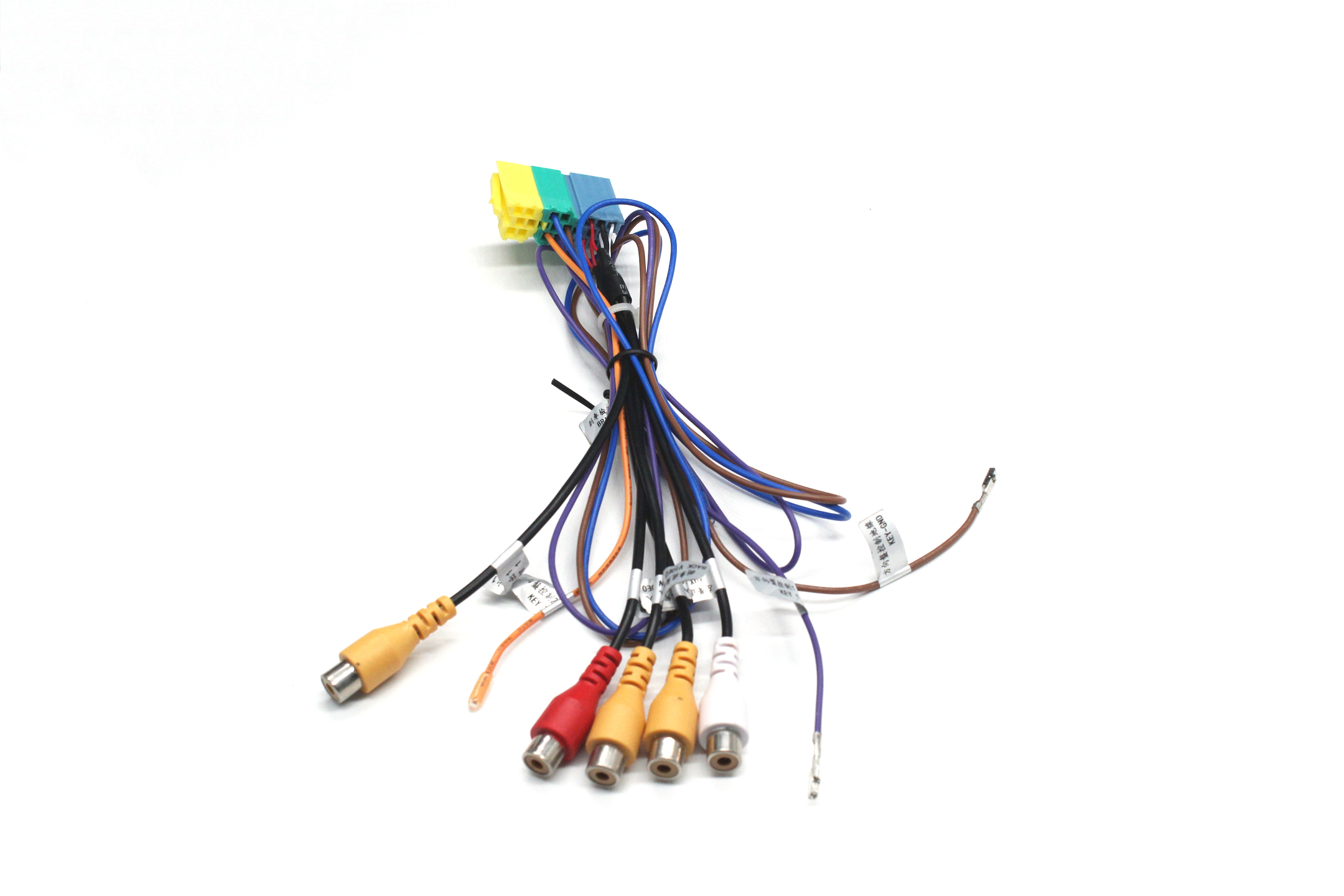

8. Terminal crimping: acknowledge whether the standards of terminals and wires are correct; Whether the terminal is pressed with a bell mouth, skewed, and whether the insulation sleeve and core wire are exposed too long or too short.

9. Terminal penetration: check whether the connector and terminal type are correct; Whether the terminal has damage, deformation and other appearance; Check whether the terminals are missing, wrongly inserted, and not fully inserted.

10. Flat wire crimping: check whether the connector type is correct; Whether the wiring direction is correct; Whether the core wire is damaged, exposed or burnt; Whether the crimping is in place.

11. Blow and shrink the short pipe: check whether the shortening of the short pipe is protruding, and the insulation skin cannot be burnt.

12. Assembly of shell: whether the shell has defects such as misplacement, scratches, burrs, etc., whether the parts are missing, whether the screws have defects such as distortion, oxidation, discoloration, looseness, etc., and whether there are non-conformities after assembly; If the housing is oriented, it must be assembled as required.

13. Labeling: check whether the label content is correct, clear and free of hyphenation; Whether the label scale is correct; Whether the label is dirty or damaged; Whether the label is pasted in the correct direction.

14. Tie: check whether the standard, color and orientation of the tie are correct; There is no crack or looseness.

15. Injection molding: check whether there is dirt on the mold, and whether there is lack of material, bubbles, poor adhesion, hardening, etc. in the molding part.

16. Plug molding: check whether the plug molding has defects such as damage, unevenness, lack of material, burr, debris, streamline, and admit that the metal terminal has no defects such as deformation, damage, copper exposure.

17. Electrical inspection: inspection shall be conducted according to the requirements of the inspection instruction ticket of the corresponding goods.

18. Appearance inspection: pay attention to all visible items.

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd