When cars no longer appear in people's eyes as luxury goods, the sales of cars began to soar,Automotive wiring harnessThe market is also gradually expanding. More and more wire harness processing manufacturers attach importance to the processing and production technology in automobile wire harness, and their processing and production technology in automobile wire harness is also becoming more and more perfect and mature. The standard and reliability of automobile wiring harness directly affect the service life and safety performance of automobile. The processing and production of automobile wire harness usually consists of the processing of wire, contact terminal (connector), sheath and other parts. Here, the automobile wire harness factory will introduce the processing and production process of automobile wire harness.

Crimping process: the terminal crimping of automobile wire harness shall be carried out in strict accordance with the instructions. Some wire harnesses will be crimped with waterproof plugs, while others need to be crimped with protective sleeves and returned from the pre-assembly station. These stations need to be spot checked and supervised at any time. The production process of wire harnesses in automobile wire harnesses is generally much more strict. Strict quality requirements are the basis for enterprises to establish a long-term foothold.

Cutting process: The complete step should be that the warehouse keeper issues materials according to the material requisition and leads the production department to cut corrugated pipes, PVC pipes and fiberglass pipes. The cutting section should be complete, but this cutting process can also be called supplier operation. Then cut and strip the car wire. There should be no deviation between the line opening requirements and the length. The length is usually set on the display panel. The line opening personnel need to monitor at any time, and the length, line cutting cut and line stripping length should be checked. The wire opening process directly affects the subsequent production process of automobile wire harness and the whole production schedule.

Pre-assembly process: the delivery date and quality assurance of automobile wire harness processing and production largely depend on the setting of the pre-assembly station. The rationality of the pre-assembly process directly affects the efficiency of wire harness assembly, and also reflects the professional skills of the R&D personnel. Setting pre-assembly station in the car harness requires engineers to summarize and optimize at any time on the site. Many manufacturers have also made many attempts in the assembly of car harness, and continue to optimize and improve. To avoid too much work in one station and too little work in other stations, it is still necessary for the person in charge to constantly summarize experience on site.

General assembly process: according to the assembly platform designed by the R&D department, design the specifications and dimensions of tooling equipment, imported electronic components, and material boxes, and paste all assembly jackets and nearby numbers on the material boxes to improve the assembly efficiency. Each tooling position needs to set the assembly content and requirements to prevent the workload of each position from being too large, thus affecting the progress of the entire assembly line.

The processing and production process of automobile harnesses directly affects the use and safety of automobiles. Automobile manufacturers should pay attention to the process and production of automobile harnesses when selecting automobile harness factories.

Basic process of harness production

1、 Acceptance link: the harness manufacturer said that it is mainly an acceptance of incoming materials. ROHS instruments or other instruments can be used for basic tests. The main harmful substances for acceptance are lead, mercury, cadmium, brominated biphenyl polybrominated diphenyl ether, etc.

2、 Put the qualified wire on the transfer wire rack for wire delivery. At this time, you should pay attention to avoid scratching the surface of the wire.

3、 Thread cutting: At this time, the thread cutting machine should be used to cut the wire into the required length.

4、 Peeling: the insulation skin is carried out according to the requirements of sop, mainly using pneumatic peeling machine.

5、 Twist wire: arrange and twist conductors at joints. Mainly use twisting machine.

6、 Riveting: use the terminal machine to rivet the conductor at the joint with the plug terminal.

7、 Assembly: assemble the processed harness, mainly the plastic plug housing.

8、 Test: The product can be packaged only after passing the final test.

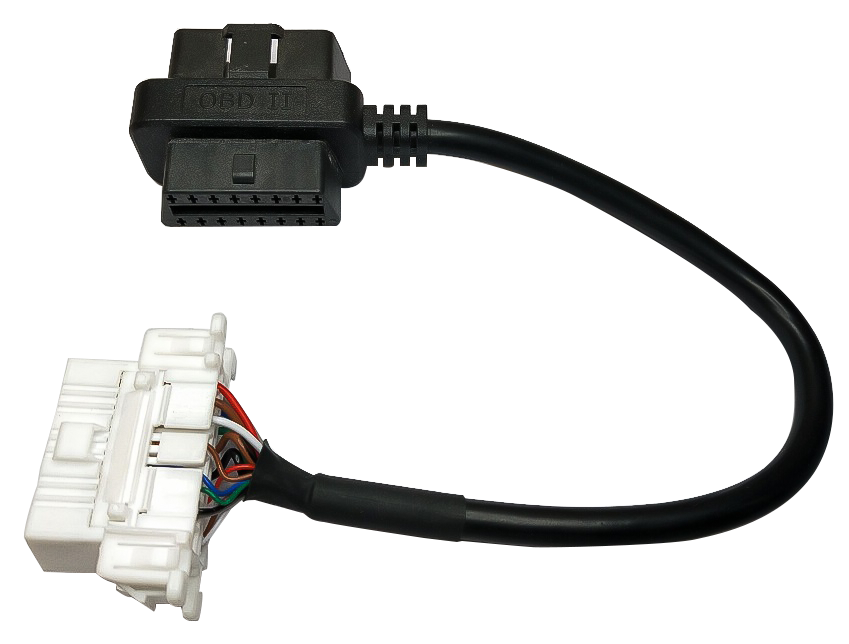

Manufacturer of on-board harness, new energy charging pile harness, terminal harness, vehicle OBD2 diagnostic cable, LVDS harness

Copyright: Shenzhen Robust Electronics Co., Ltd